It is a very common method used widely in the business especially in the manufacturing sector, and in this way the company is able to determine the cost of individual product and services. Absorption costing is not only a absorption costing tool for internal management but also crucial for compliance with external financial reporting standards. It aligns with the Generally Accepted Accounting Principles (GAAP) and International Financial Reporting Standards (IFRS), ensuring that financial statements present a comprehensive view of a company’s health. Cost allocation in absorption costing means distributing costs evenly across all units produced.

Accurate Cost Allocation

- Under this method, prime cost is used as the basis for determining the overhead absorption rate.

- Indirect costs are those costs that cannot be directly traced to a specific product or service.

- Suppose we have a fictional company called XYZ Manufacturing that produces a single product, Widget X.

- This technique takes into account the interdependencies between cost centers and allocates costs accordingly.

- ABC Retail Chain operates a network of stores across the country, offering a wide range of products to customers.

- Absorption costing is a widely used methodology for allocating costs in manufacturing companies.

The Absorption Cost Calculator per Unit is a crucial tool in managerial accounting and cost Insurance Accounting accounting. It helps in determining the total cost per unit of a product, including all direct and indirect costs. Additionally, it is not helpful for analysis designed to improve operational and financial efficiency or for comparing product lines. In addition, the use of absorption costing generates a situation in which simply manufacturing more items that go unsold by the end of the period will increase net income.

Absorption Costing vs. Variable Costing

- While absorption costing is mandatory for external reporting under GAAP and for tax reporting by the IRS, leveraging other costing methods can be beneficial for specific internal business insights.

- With absorption costing, these fixed costs are spread across all units produced, giving a clearer picture of the true cost per unit.

- Management might implement strategies such as lean manufacturing to reduce waste, optimizing both fixed and variable overheads.

- In conclusion, cost allocation techniques in absorption costing are essential for accurately assigning costs to products or services.

- This level of detail not only complies with GAAP standards but also provides a granular understanding of product costing, facilitating better strategic decisions.

- This includes cases where a company is required to report its financial results to external stakeholders, such as shareholders or regulatory agencies.

This limitation effectively restricts the use petty cash of variable costing for external financial statements, emphasizing the critical role the matching principle plays in shaping GAAP-compliant accounting practices. Such multi-layered calculations underscore the intricate nature of absorption costing, revealing that even a seemingly simple formula can necessitate an in-depth understanding of production details and cost factors. Direct labor refers to the wages paid to workers who are directly involved in the manufacturing process. These are employees who physically create or assemble the product, making their role crucial in production. It complies with generally accepted accounting principles and offers a comprehensive approach to determining the actual cost of products.

- Absorption costing means that ending inventory on the balance sheet is higher, while expenses on the income statement are lower.

- Step-down allocation, also known as sequential allocation, is used when costs cannot be directly traced to individual products or services.

- These costs include raw materials, labor, and any other direct expenses that are incurred in the production process.

- By accurately allocating direct and indirect costs using absorption costing, the company can determine the true cost of producing each piece of furniture.

- Absorption costing can sometimes skew profitability assessments, particularly when production levels vary significantly.

Monitoring Production Volume

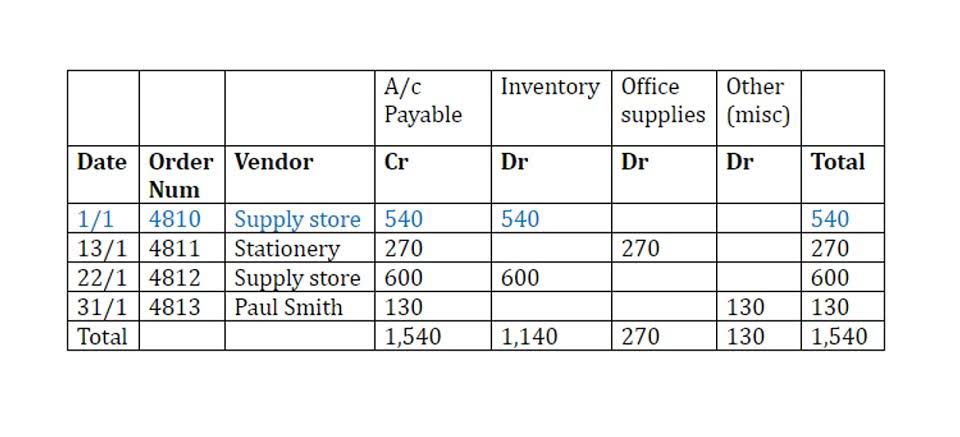

Absorption costing is a widely used method for allocating costs to products or services. It involves the allocation of both variable and fixed costs to units produced, making it a comprehensive approach to cost allocation. In this section, we will explore the advantages and disadvantages of absorption costing. By applying absorption costing, Company XYZ can accurately determine that each bicycle produced incurs a total cost of $100, considering all direct materials, direct labor, and fixed manufacturing overhead costs. Regularly review and adjust overhead costs to match any changes in your production process. Shifts in fixed costs, direct labor costs, or the price of direct materials can affect total production expenses.

- This application of overheads is called absorption, which can be defined as the charging of overheads to production.

- The company’s cost accountants must precisely identify these varying factors and incorporate them into the absorption costing calculations for each product type.

- In this example, using absorption costing, the total cost of manufacturing one unit of Widget X is $28.

- This is an excellent method for the absorption of overhead costs in industries where much of the work is performed with the help of machines.

- You need to allocate all of this variable overhead cost to the cost center that is directly involved.

- When we prepare theincome statement, we will use the multi-step income statementformat.

- To allocate costs, XYZ uses a combination of direct allocation and step-down allocation.

WD & Co.: Analyzing Dog Coat Manufacturing Costs

The following is the step-by-step calculation and explanation of absorbed overhead in applying to Absorption Costing. This streamlining improves the accuracy of financial reporting and enhances the visibility of cost components, reducing manual errors and time-consuming processes. Implementing absorption costing poses several challenges that businesses should consider.

This comparative lens underscores the critical differences between absorption and variable costing, providing a nuanced understanding of how each method impacts financial reporting and decision-making. For instance, consider an apparel company producing both scarves and dresses in the same facility using identical fabric. Though both products share a common material, the amount of fabric and labor required for each differs significantly. The company’s cost accountants must precisely identify these varying factors and incorporate them into the absorption costing calculations for each product type. Overall, absorption costing gives businesses a better understanding of all the costs involved in production and ensures compliance with industry standards. Usually, the amount of the overheads and the value of direct materials are determined from past experience, and the overhead rate is calculated in advance.

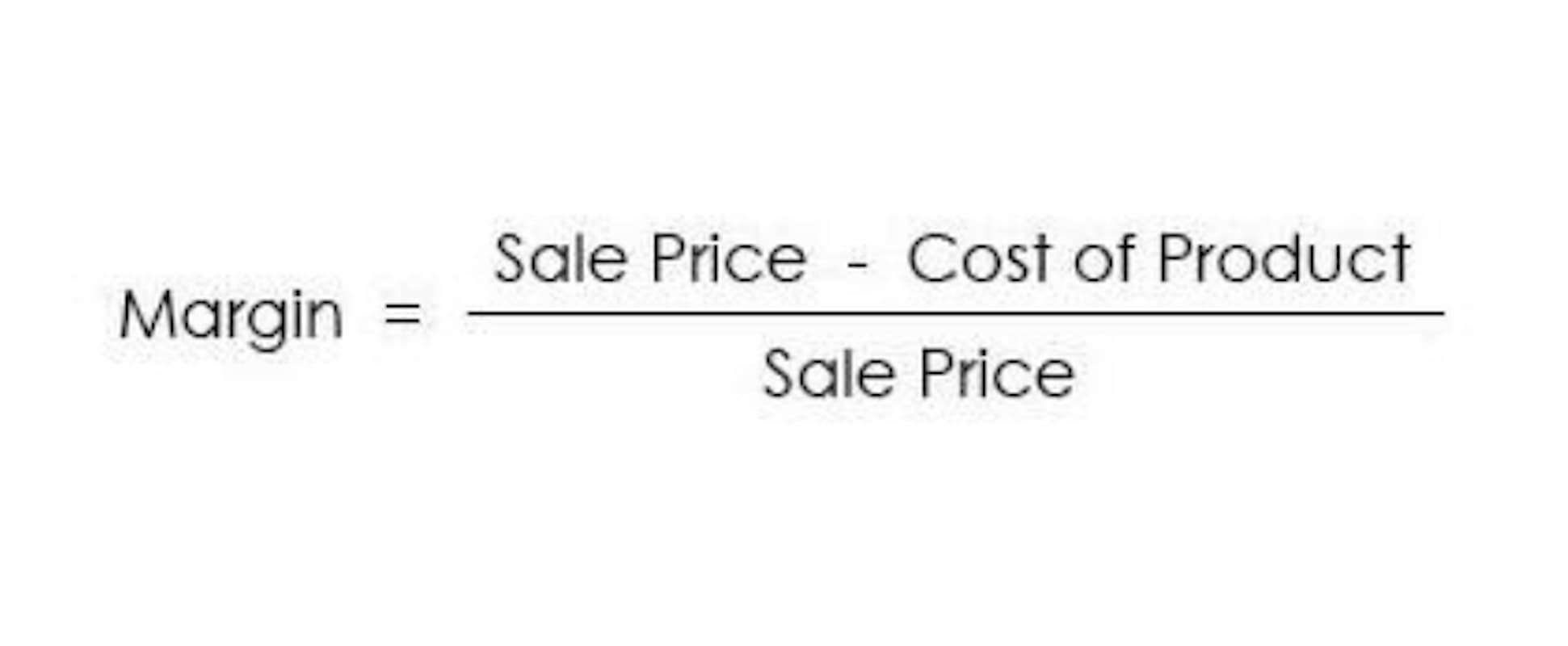

However, this can result in excess inventory, storage costs, and potential write-offs if the products cannot be sold. An effective review process ensures that product and period costs remain accurate, preventing discrepancies in balance sheet entries and income statements. Use a clear predetermined overhead allocation rate based on actual production volume to maintain cost accuracy and reflect all the costs involved. It is best suited to those units of production where overheads depend on both direct materials and direct labor. It is very important to understand the concept of the AC formula because it helps a company determine the contribution margin of a product, which eventually helps in the break-even analysis.

Under absorption costing, the fixed manufacturing overhead costs are included in the cost of a product as an indirect cost. These costs are not directly traceable to a specific product but are incurred in the process of manufacturing the product. In addition to the fixed manufacturing overhead costs, absorption costing also includes the variable manufacturing costs in the cost of a product. These costs are directly traceable to a specific product and include direct materials, direct labor, and variable overhead. Absorption costing, also called full costing, is what you are used to under Generally Accepted Accounting Principles.